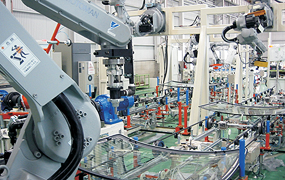

Factory Automation

Past projects

-

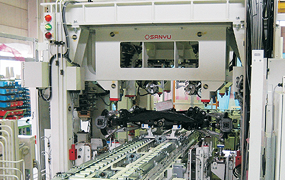

- Equipping front and rear glass DC

- Primer and adhesive polyurethane is automatically applied on the front and rear glass. A primer and polyurethane image inspection device will be equipped after.

-

- Rear suspension alignment control device

- Rear suspension, which had been sub-ASSY, is delivered through palettes. Alignment is measured and adjusted. These processes are done automatically.

-

- Auto die casting machines

- From the die cast machine, the required volume of melt is automatically injected into the float from the furnace.

-

- Die cast finishing equipment

- Machine for taking output from the die cast machine for sanding and hole cutting.

-

- Material handling robot for M/C process

- Command that take in and out products to machine tools of each process by self-propelled robot.

-

- Surface area measurement device

- With a laser sensor the machine detects the outline of the vehicle and calculates its surface area and volume.

Image Inspection Devices

-

- Seal application

- Seal application robot has a camera which will inspect the seal material’s coating width and gaps.

-

- Surface and form inspection

- The inspection of the surface and form of each work will be conducted during this process.

-

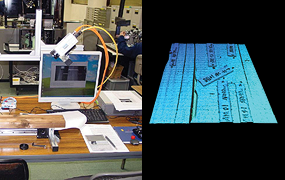

- 3D inspection device using a light section method

- A light section method will allow us to inspect the lumber’s surface.

-

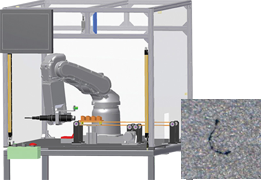

- Inspection of the surface of resin products

- By using the camera attached to the robot, we image the surface of resin parts and perform image processing inspection.